Forged rolls for cold rolling fulfill the customer's demands for increased productivity, high reliability, safety of operation, finer surface quality, higher rolling speeds, and more demanding rolled materials and thus positively influence TCO (Total Cost of Ownership).

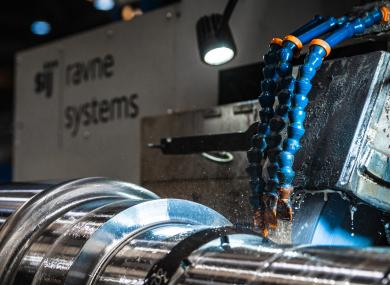

These properties are achieved with a combined heat treatment where the roll is quenched and tempered to the basic hardness first, and then the surface is hardened to reach the proper work hardeness. These rolls are surface hardened in a dual frequency induction hardening machine, followed by rapid cooling with liquid nitrogen below -140 °C, and then tempered at low temperature.

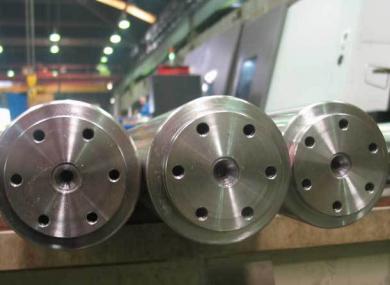

Surface hardened rolls are manufacured in the following dimesional range:

- Up to 800 (33˝) mm diameter

- Up to 5500 mm length and

- Up to 10.000 kg (22,000 lbs) weight

Surface hardened rolls are made from high quality steel in accordance with customer requirement .

DURALIFE - next generation of forged rolls

The DURALIFE family of rolls is the next generation of high-alloy rolls for cold rolling, with the brand names DURALIFE EXTRA (tool steel with 5% chromium content) and DURALIFE SUPREME (tool steel with 8% chromium content).

DURALIFE brand rolls have a longer life time, better resistance to wear and resistance to damage, and therefore longer campaigns. One of their many advantages is that, thanks to the higher levels of ferroalloys, they have longer roughness retention and chrome plating is not required.

BETTER SOLUTIONS WITH LONGER LIFE TIME!

GREGOR VEČKO

Head of Sales program Rolls

- SIJ Ravne Systems d.o.o.

- Koroška cesta 14

2390 Ravne na Koroškem, Slovenia - Lat: 46.544352 | Long: 14.949554

- +386 2 870 76 92

- gregor.vecko@ravnesystems.com ravnesystems.com