Why choose measuring machine FERRANTI MERLIN 3000XL?

MEASURING + ANALYSING = COST AND TIME SAVING

- Analysing the data and providing relevant documented recommendations and solutions.

- Specific measurements with advanced technologies

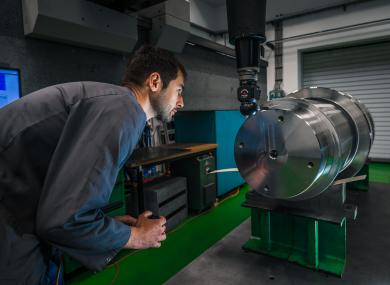

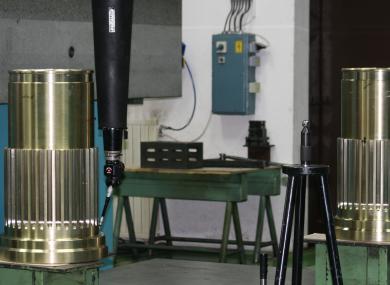

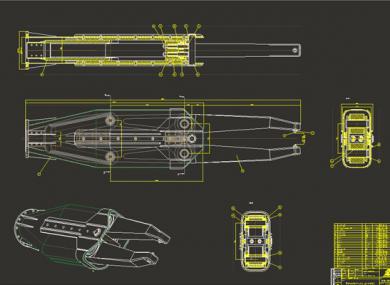

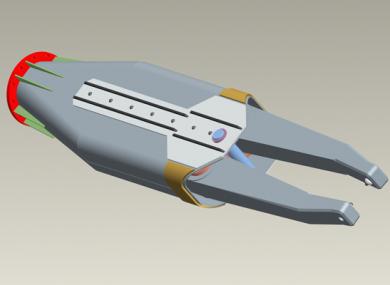

3D coordinate measuring machine FERRANTI MERLIN 3000XL

- Measure welded parts for mechanical engineering, the automotive industry, energy and space program

- Providing of quality, precision and optimal high-speed measurements at the lowest price

- 28 years of experience our qualified staff

- Implementation of annual machine calibration

FERRANTI MERLIN 3000 XL basic specifications

- Measurement of the CNC (X, Y, and Z axis) mode

- Measuring range: 3000 x 3500 x 1500 mm

- Measured maximum weight: 10 tons

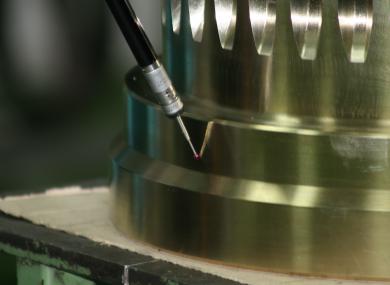

- Declared accuracy of the machine: 7 + 8 * L / 1000 mm, where L is the length of the measurement

- Suited for dimensional control rate with very narrow tolerances

- Application software PC DMIS CAD (possibility to measure the 3D CAD models)

- The final protocol and technical interpretation of measurements

EQUIPMENT OVERHAUL AND REFURBISHMENT

Ravne Systems' overhaul and refurbishment programs bring old equipment back to its original condition.

- From single components to complete equipment overhaul and refurbishment

- Dedicated team of specialists

- Increased efficiency of equipment and extended life time

- Cost and time savings

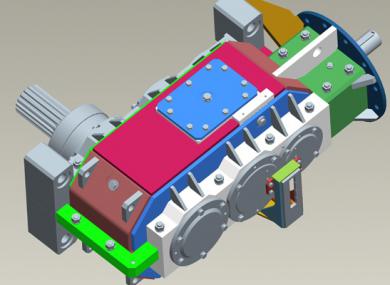

ENGINEERING AND TECHNICAL IMPROVEMENTS

Ravne Systems, with its dedicated team of specialists, is constantly searching for and developing technical solutions for both old and new equipment in order to reduce operational and maintenance costs.

- New uses for existing equipment

- Improvement in efficiency and availability

- Removal of process bottlenecks

TRANSFORMATION ↔ MODIFICATION ↔ UPGRADING

TECHNICAL INSPECTIONS WITH DIAGNOSTIC AND DATA EVALUATION

Ravne Systems, with its on-site technical inspections and related diagnostics, offers support in the evaluation of the state of equipment, the detection of process bottlenecks and the relevant technical improvements.

- Specific measurements with advanced technologies

- Analyzing the data and providing relevant documented recommendations/solutions

- Understanding process parameters and the analysis of causes of damage

MEASURING + ANALYZING = COSTS AND TIME SAVING

REPAIRS AND MAINTENANCE

Periodic overhaul of machines and related components extend the life of equipment, preventing possible breakdowns and increasing safety, reliability and efficiency.

- Maintenance planning

- Emergency repairs

MAINTENANCE STRATEGY = EQUIPMENT RELIABILITY AND INCREASE IN PRODUCTION

BLAŽ SMONKAR

Head of Maintenance & Machine building

- SIJ Ravne Systems d.o.o.

- Koroška cesta 14

2390 Ravne na Koroškem, Slovenija - Lat: 46.544352 | Long: 14.949554

- +386 2 870 62 55

- blaz.smonkar@ravnesystems.com ravnesystems.com