For debarking, log peeling and slicing of veneer, in vertical and horizontal slicer machines and rotary lathes.

Product range:

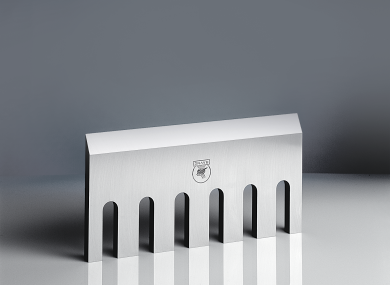

- Veneer peeling knives

- Veneer slicer knives

- Veneer guillotine knives

- Rotary clipper knives

- Pressure bars

- Spur knives

- Debarking knives and composer knives, etc.

We produce knives which are compatible with wood cutting machines produced by all major global manufacturers, such as: Grenzebach, Cremona, Keller, Kralovopolske, Capital, Coe, Fezer, Raute, Marunaka, Uroko, Valette & Garreau, and others.

First-class raw materials, professional heat treatment for good wear resistance and precise machining for dimensional accuracy with blemish-free surfaces for superior cutting performance and quality of end products.

As we are a tool steel producer and have extensive application experience we are able to help you find the most suitable quality for your cutting process, which is reflected in the durability of the knives, increased machine uptime, lower energy consumption and enhanced machine output. We help you to optimize your production process, reduce downtime and lower your tool costs.

What are the key benefits of SIKNIVES?

Find out more about comparison of STANDARD KNIVES and SIKNIVES in the attached leaflet.

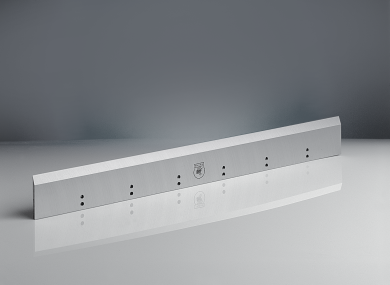

INNOVATIVE PRESSURE BAR

Improved technology - CNC controlled PTA surfacing

In SIJ Ravne Systems we are welding special wear-resistant alloy, with the new method of manufacture for the base used structural steel. This is extremely resistant to tannin, which is the main culprit for the rapid wear of the blade from the classic tool steel. Welded portion represents only 10% of the weight of the product. The core of the product is made of structural steel, that retains durability required to carry the load during the operation of embedded product which is a PRESSURE BAR.

ADVANTAGES OF PTA PROCESS:

- Metallurgical homogenity

- High energy efficiency

- Limited heat addition

- Flexibility of the system

- Constance of results

- High welding speed

We offer our customers three components which are basically used for machines for peeling veneer:

- Knives for veneer

- Spur knives (knives for trimming the width)

- Pressure bar (to adjust the thickness of the veneer)

PRESSURE BAR and its importance:

- Setting the pressure bar to the machine for peeling veneer is a complex process, about 4 - 6 hours.

- The advantage of our bar with welded part is that we change it once per month.

- Weld portion has in fact a better sliding properties and less damage to the surface of the veneer.

Simon Vergles

Sales Project Manager

- SIJ Ravne Systems d.o.o.

- Koroška cesta 14

2390 Ravne na Koroškem, Slovenija - Lat: 46.544352 | Long: 14.949554

- +386 2 870 62 26

- simon.vergles@ravnesystems.com ravnesystems.com